Inteligize Process Engineering

In the ever-evolving landscape of process design and

engineering, the integration of AI with established process models and engineering expertise

presents a transformative opportunity. The core mission of management remains steadfast:

increasing process throughput, enhancing quality, and reducing costs. Achieving these objectives

requires a nuanced understanding of how output variability can arise from fluctuations in input

materials and process conditions. By carefully analyzing the trade-offs between product

quantity, quality, and energy consumption, organizations can determine the optimal batch size

that maximizes efficiency while minimizing waste.

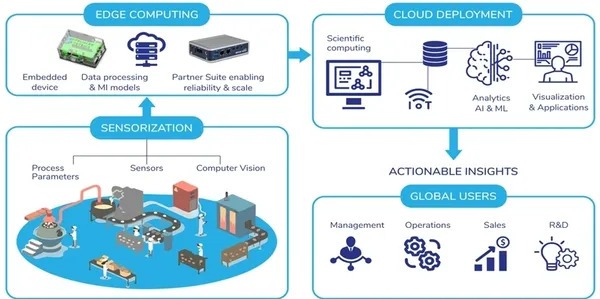

In today’s fast-paced environment, effective solutions must encompass several key features to be

truly impactful. They should leverage the underlying physical laws of the system to provide

explainable results, while also utilizing a variety of validated process data for accurate

predictions. Real-time insights with enterprise-wide access are essential, as is an app-like

user experience that minimizes the need for advanced technical knowledge. Intelimek’s Digital

Twin solutions exemplify this approach, delivering a comprehensive framework that meets the

demands of modern process engineering while enabling organizations to navigate complexity with

confidence.