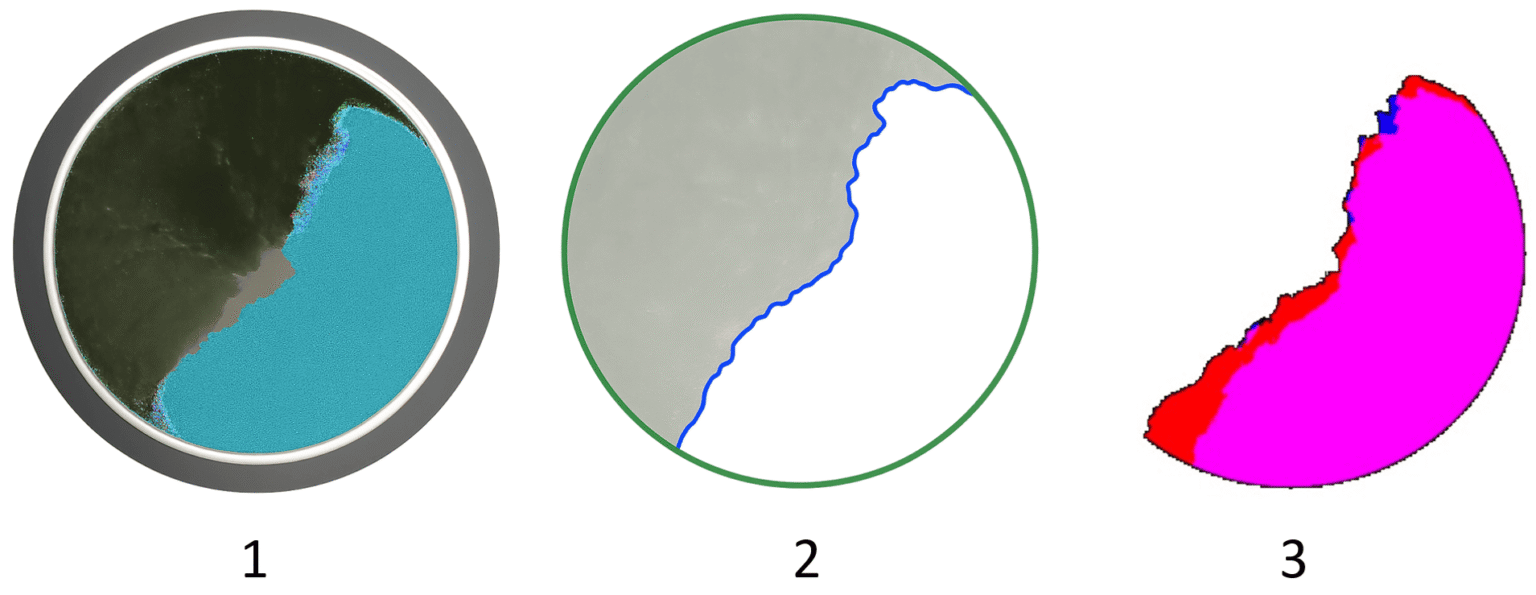

Digital Twins for Unit Operations

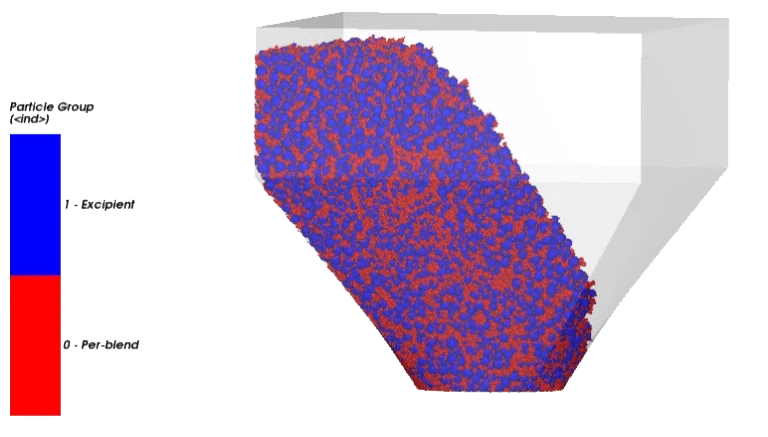

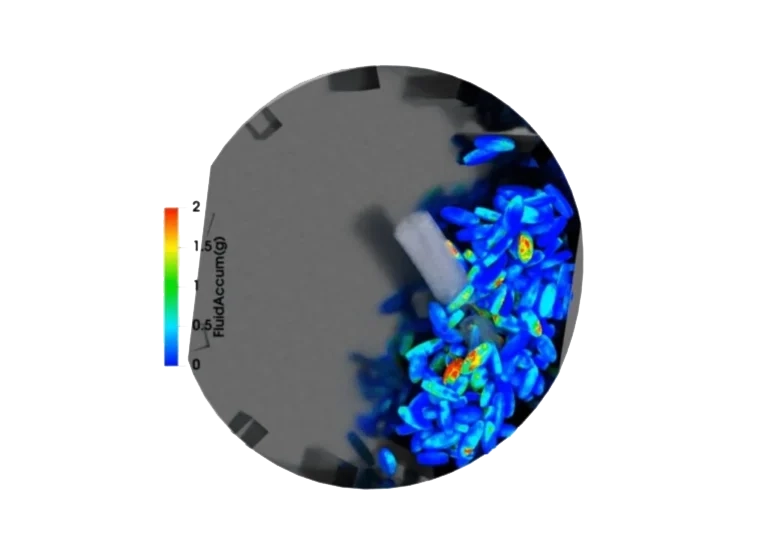

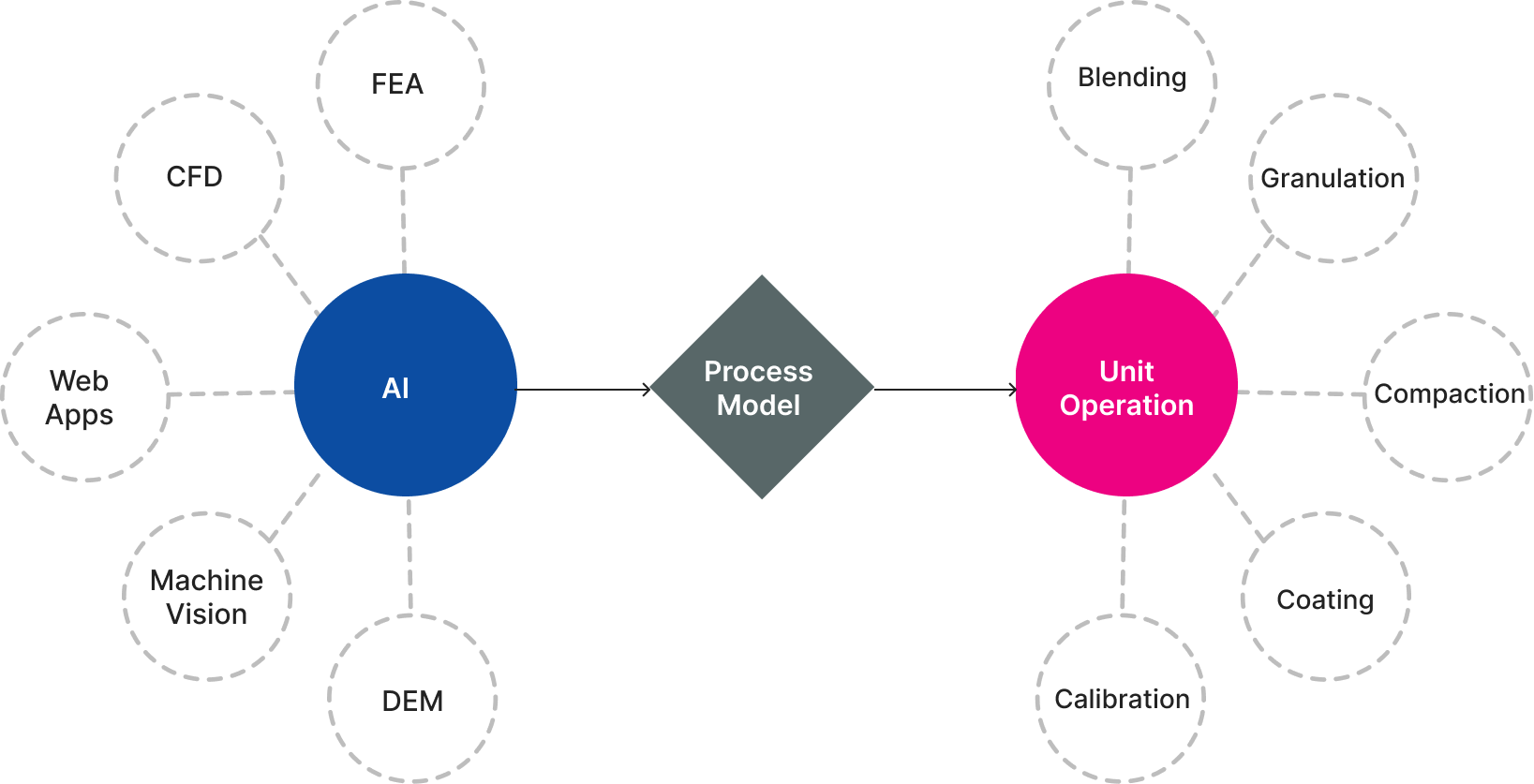

At Intelimek, we are transforming pharmaceutical manufacturing by offering a complete Software-as-a-Service (SaaS) solution that integrates advanced Digital Twin technology with comprehensive support services. Our offering isn’t just a digital twin platform—it’s a full-service web application that performs high-fidelity simulations, AI/ML model training, and process optimization across critical unit operations such as blending, granulation,film coating, drying, direct compaction. By combining state-of-the-art simulation techniques (FEA, DEM, CFD) with AI, cloud-based processing and expert services, we help you enhance process efficiency, reduce waste, and ensure the highest product quality.