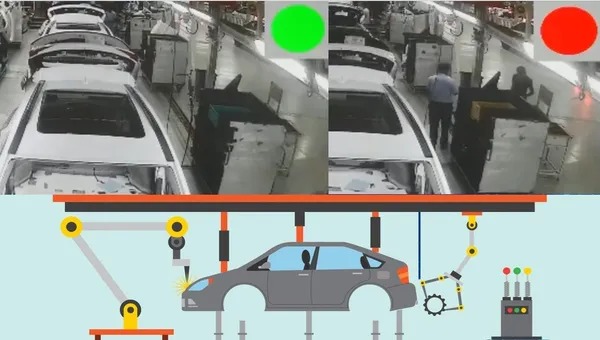

Challenges & Objective

- Hammer test is performed to check the quality of the weld

- Error-prone as well as involves risk of injury or human life

- Any weld failure in the process causes complete shut down of the mill resulting into heavy losses

Solution

- Hammer test is replaced with ultrasonic head scanning the complete weld

- Real time analysis of ultrasonic scan data to assess the metal thickness variation along the length of the weld

- Machine learning of the processed scan data for prediction of weld quality